Isistimu ye-conveyor iphatha ngokuhlelekile futhi ithuthe izinto, ngokuvamile endaweni yezimboni noma elawulwayo.Amabhande e-Conveyor ayisilondolozi samandla esizanyiwe neseqiniso esidizayinelwe ukukhulisa ukusebenza kahle.Ake sibheke ukuthi amabhande okuthutha asebenza kanjani nokuthi kungani emile isikhathi eside.

Lisebenza Kanjani Ibhande Leconveyor?

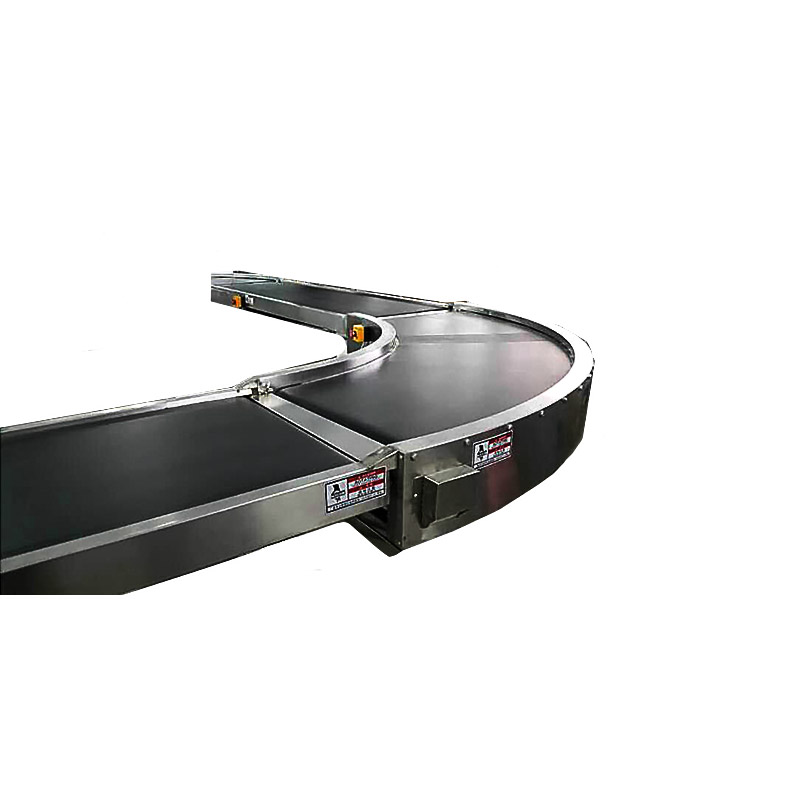

Ibhande lokuthutha lisebenza ngokusebenzisa amapulley amabili anenjini ajikela phezu kwento ewugqinsi, eqinile.Lapho ama-motor kuma-pulleys esebenza ngesivinini esifanayo futhi ejikeleza ohlangothini olufanayo, ibhande lihamba phakathi kokubili.

Uma izinto zinzima kakhulu noma zikhulu kakhulu - noma umaibhande lokuthuthaiwathwala ibanga elide noma ubude besikhathi - ama-roller angase abekwe ezinhlangothini zebhande lokuthutha ukuze asekele.

Izingxenye Zohlelo Lwebhande Le-Conveyor

Yize kunezinhlobo eziningi zezinhlelo zokuthutha, zonke zisebenzisa inhloso efanayo yokuthutha izinto.Eminye imikhiqizo ingase idinge isistimu ngaphandle kwebhande, isebenzisa kuphela ama-roller noma amasondo ukunyakaza okuguquguqukayo.Kodwa-ke, amasistimu amaningi okuthutha ancike kuhlaka olunebhande kanye namarola asekelayo okungenzeka aphathe izinto kanye nemikhiqizo ngendlela efanele.

Wonke amasistimu okuthutha anezingxenye ezintathu eziyinhloko - iphrofayili ye-aluminium, iyunithi yokushayela kanye neyunithi ye-extremity.

Kusistimu yebhande le-conveyor, iphrofayili ye-aluminium iqukethe uhlaka, ibhande nanoma yiziphi izisekelo.Amasistimu asebenzisa ibhande ngokuvamile anikwa amandla injini, nakuba amasistimu okuthutha angasebenzisa amandla adonsela phansi noma amandla okwenziwa ngesandla ukuze asebenze.Amabhande okuthutha anezimoto alungele ukusetshenziswa ezimbonini njengoba ethembeke kakhulu futhi esebenza kahle - iyunithi yokushayela yamasistimu anjalo izohlanganisa ubakaki wezimoto, ukushayela kukagesi nanoma imaphi ama-counter bearings.

Iyunithi yomkhawulo yesistimu yebhande lokuthutha ngokuvamile ihlanganisa noma yimaphi ama-pulley namabhande okubopha.Izitendi ezengeziwe noma imihlahlandlela esemaceleni ingase idingeke ukuze uthole ukuhluka okuthile noma imisebenzi, ngakho-ke cabangela izidingo zomkhakha wakho lapho ukhetha lezi zengezo ozikhethela zona.Izingxenye nemisebenzi yesistimu yebhande lokuthutha ingase ihlanganise:

● Uhlaka: Uhlaka lwesistimu lubamba zonke izingxenye ezihambayo ndawonye ukuze zisebenze ngokuphephile nangokuvikelekile.

● Ibhande: Ibhande elide lezinto eziwugqinsi, ezihlala isikhathi eside okuthutha ngazo izinto zisuka kwenye indawo ziyiswe kwenye.

● Ibhande elisekela ibhande lokuthutha: Amarola asiza ibhande ukuthi lihlale endleleni futhi ligcine ukunyakaza ngokushesha.Amarola agcina izinto endaweni futhi avimbele ibhande ukuthi lingantengi.

● Iyunithi yokushayela: Izinjini zingasebenzisa amagiya okwehlisa isivinini aguquguqukayo noma angashintshi ukuze anike amandlaibhande lokuthutha.Iyunithi yokushayela esebenza kahle kufanele ihlale isiza ibhande ngokugijima okuqhubekayo, ukuhlehla okushelelayo kanye nokulungisa ngokuphindaphindiwe indlela eya ngakuyo.

● Ama-pulley: Ibhande lokuthutha kufanele lijike phezu kwamapulley amabili noma ngaphezulu amiswe ngendlela efanele.I-pulley ilawula ukunyakaza kwebhande futhi lenza imisebenzi ebalulekile njengokushayela, ukuqondisa kabusha, ukujika, ukuqina nokulandelela ibhande.

● Izintambo zokubopha: Izintambo zokubopha zisetshenziswa emishinini ehlukahlukene ukuze zibambe izinto ezifakiwe kanye nezinto zokusebenza.

● Amamojula okwengeza: Izingxenye eziningi ezengeziwe zifakiwe ukuze ziqiniswe ngokwengeziwe.Ngenkathi ama-roller esekela ibhande ngaphakathi kwesistimu, izitendi neziqondiso ezisemaceleni zisekela uhlaka lwangaphandle.

Ukubhinca i-conveyor kungenziwa ngezinto ezahlukahlukene, kufaka phakathi irabha, insimbi, isikhumba, indwangu kanye nepulasitiki.Cabangela izimo uhlelo lwakho oluzosebenza ngaphansi kwazo ukuze uqinisekise ukuthi impahla yokubopha i-conveyor iwugqinsi namandla afanelekile.

Isikhathi sokuthumela: Mar-07-2023